Measure What Matters: Achieving Accurate & Efficient Volume Calculations with Drone Technology

I. Introduction: The Challenge of Measuring Bulk Materials

Accurate volume measurement is fundamental to success in industries that handle bulk materials, including construction, mining, aggregates, and landfill management. Knowing precisely how much material – be it soil, gravel, sand, ore, coal, or waste – is on-site is critical for effective inventory management, production tracking, project bidding, financial reporting, contractor payment verification, and ensuring regulatory compliance.25 However, traditional methods for measuring stockpiles and earthwork volumes are often fraught with challenges. Manual surveying using GPS rovers or total stations can be incredibly time-consuming, labor-intensive, and costly, requiring skilled personnel and potentially disrupting site operations.25 Methods like truck counting are notoriously inaccurate. Furthermore, traditional surveying often involves personnel climbing onto potentially unstable stockpiles or working in close proximity to heavy machinery, posing significant safety risks.23 The inherent inaccuracies and inconsistencies of these older methods can lead to costly errors in inventory valuation, project estimation, and resource allocation.25

Drone technology offers a powerful and efficient solution to these long-standing challenges. Unmanned Aerial Vehicles (UAVs) equipped with advanced sensors and paired with sophisticated software provide a method for calculating volumes that is significantly faster, safer, more accurate, and often more cost-effective than traditional techniques.23This technological shift transforms stockpile measurement from an infrequent, labor-intensive, and potentially hazardous task into a routine, efficient, and safe operational process. The speed and ease of drone deployment allow for much more frequent measurements – weekly, daily, or even on-demand – enabling near real-time inventory management and more dynamic production planning, rather than relying on periodic, often outdated, estimates.23 This capability provides site managers with unprecedented control and visibility over their material assets. Moreover, the high accuracy and detailed 3D data captured by drones provide an objective and verifiable record of material quantities. This minimizes disputes over volumes between suppliers, contractors, and clients, leading to smoother commercial transactions, more accurate billing, and improved financial reconciliation based on reliable data.26 SimpliFly specializes in delivering this precise volumetric data, empowering businesses to measure what truly matters with confidence.

II. The SimpliFly Advantage: Precision Volumetrics On Demand

Leveraging SimpliFly’s drone services for volume calculations provides numerous operational and financial advantages compared to traditional measurement methods.

- Increased Accuracy: This is a primary benefit. Drones capture the entire surface geometry of stockpiles and earthwork areas with high density, allowing software to calculate volumes based on the true shape, not just a few estimated points.25 This significantly reduces the inaccuracies inherent in manual methods. Depending on the technology used (Photogrammetry or LiDAR) and the implementation of ground control (GCPs or RTK/PPK), accuracies of 1-2% or even survey-grade precision (e.g., 20-50mm) are achievable.26 This minimizes costly errors associated with inaccurate inventory or earthwork calculations and reduces human error.25

- Faster Data Collection: Drones can survey large sites with multiple stockpiles or extensive earthwork areas in a matter of hours, a task that could take days for ground crews.23 SimpliFly can potentially cover up to 500 acres per day, enabling rapid data acquisition for timely decision-making.12

- Improved Safety: Drones eliminate the need for personnel to physically climb onto potentially unstable stockpiles or walk across active work sites near heavy equipment, drastically reducing exposure to hazards and improving overall site safety.23

- Cost-Effectiveness: The speed and reduced labor requirements of drone surveys translate directly into cost savings compared to traditional methods.23 Eliminating the need for site shutdowns during surveys further enhances operational efficiency and reduces indirect costs. Case studies demonstrate significant ROI, including direct cost savings on specific jobs and increased overall revenue due to efficiency gains.50

- Comprehensive Data & Documentation: Drone surveys provide not only volume calculations but also high-resolution aerial imagery (orthomosaics) and 3D models.73 This visual context is valuable for site planning, communication, and record-keeping. The digital data creates a verifiable historical record, allowing for easy tracking of stockpile changes or earthwork progress over time.26

SimpliFly utilizes two primary drone technologies for volumetric surveys:

- Photogrammetry (RGB Cameras): This method involves capturing a large number of overlapping, high-resolution aerial photos of the site.14 Specialized software then processes these images, using common features to triangulate points in 3D space and generate a detailed 3D model and orthomosaic map of the area.14 Volumes are calculated from this 3D model. Photogrammetry is often highly cost-effective and provides rich visual data alongside the measurements.27

- LiDAR (Light Detection and Ranging): LiDAR sensors mounted on drones emit laser pulses and measure the reflected light to directly capture millions of precise 3D coordinate points (a point cloud) representing the surfaces below.28 This technology is known for its high accuracy, particularly in capturing complex shapes and terrain, and its ability to function well in various lighting conditions. Volumes are calculated directly from the dense point cloud data.40

- Accuracy Enhancements: To ensure the highest level of accuracy required for many volumetric applications, both photogrammetry and LiDAR surveys often incorporate Ground Control Points (GCPs) – precisely surveyed markers on the ground – or utilize drones equipped with RTK (Real-Time Kinematic) or PPK (Post-Processed Kinematic) GPS technology. These methods correct for minor inaccuracies in the drone’s GPS positioning, tying the aerial data accurately to real-world coordinates.25

While both technologies can deliver accurate volumetric results 27, the optimal choice may depend on specific project factors. Photogrammetry might be preferred for its lower cost and rich visual output when extreme precision isn’t the absolute priority. LiDAR might be chosen for its superior accuracy in complex terrain, its ability to penetrate light vegetation (less relevant for bare stockpiles), or potentially faster data processing times. Material properties, like high reflectivity, can sometimes pose challenges for LiDAR. SimpliFly provides expert guidance to help clients select the technology that best balances accuracy requirements, budget, site conditions, and desired turnaround time.

III. How Drone Volumetrics Work: From Flight to Figures

The process of obtaining accurate volume calculations using drones involves several key stages, managed expertly by SimpliFly:

A. Data Capture

- Flight Planning: Careful planning is essential for accurate results. SimpliFly pilots design automated flight paths (often grid or cross-hatch patterns) using specialized software to ensure complete coverage of the stockpile(s) or earthwork area, with sufficient image overlap (typically 70-80% for photogrammetry).10 Flight altitude, speed, and camera/sensor settings are optimized based on the desired resolution and site conditions.14 If required for highest accuracy, Ground Control Points (GCPs) are strategically placed and surveyed across the site before the flight.26

- Data Acquisition: The drone autonomously executes the pre-planned flight mission. For photogrammetry, it captures hundreds or thousands of high-resolution, geotagged images from multiple angles.14 For LiDAR, the sensor emits laser pulses and records the return times, generating a dense stream of 3D points as it flies.25

B. Data Processing

- Software Processing: The captured raw data (images or LiDAR point data) is transferred and processed using powerful photogrammetry or LiDAR processing software (common platforms include DroneDeploy, Pix4D, Trimble Stratus, Agisoft Metashape, RealityCapture, LP360, YellowScan CloudStation).5

- Model Generation:

- Photogrammetry: The software analyzes the overlapping images, identifies common tie points, and uses triangulation algorithms (Structure from Motion – SfM) to calculate the 3D position of millions of points, creating a dense point cloud. This point cloud is then often converted into a textured 3D mesh (surface model) and a high-resolution orthomosaic map.20

- LiDAR: The raw laser return data is processed to generate a precise 3D point cloud. This often involves filtering out noise or erroneous points (e.g., points reflected from dust or equipment) and classifying points (e.g., ground vs. non-ground).40

- Georeferencing: Data from GCPs or the drone’s RTK/PPK system is used during processing to ensure the resulting point cloud, 3D model, and orthomosaic are accurately positioned in the desired real-world coordinate system.25

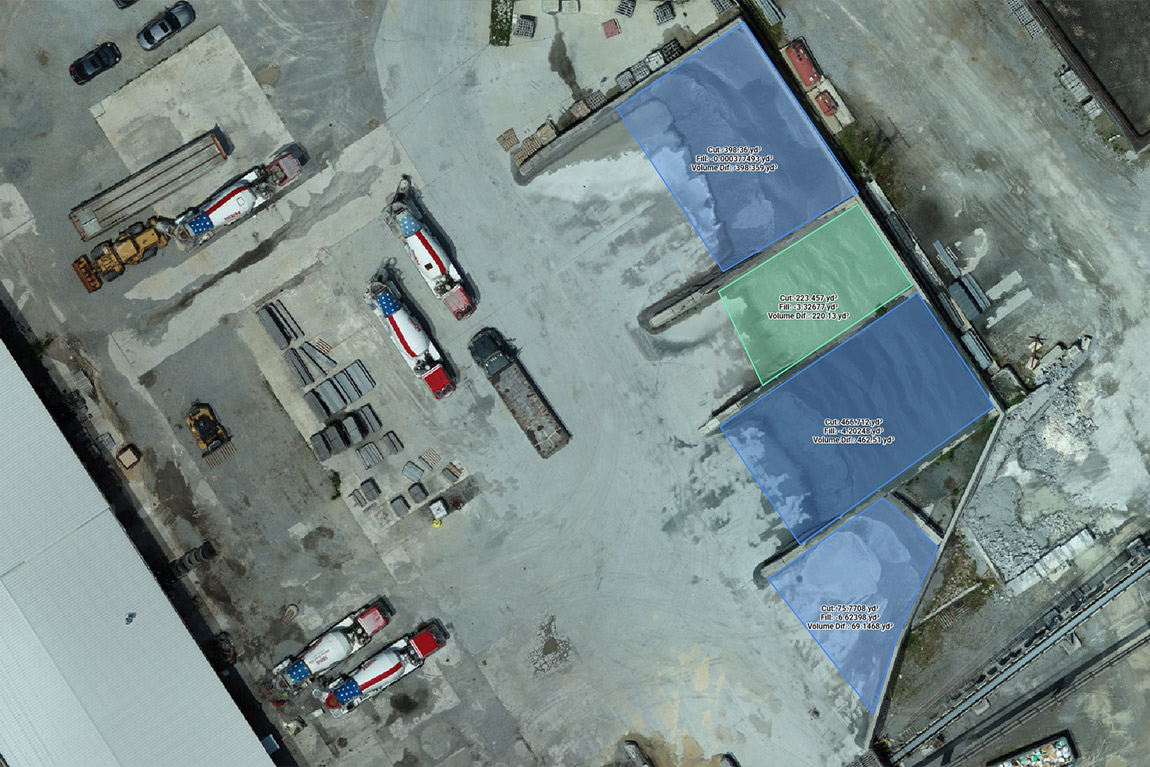

C. Volume Calculation & Reporting

- Defining Boundaries/Base Surface: Within the processing software, the operator defines the extent of the stockpile or excavation area on the 3D model or point cloud.25 This typically involves outlining the “toe” or perimeter of the pile. A base surface must also be established, against which the volume will be calculated. Common methods include:

- Level Base: Assuming a flat base at a specific elevation.

- Interpolated Base (Smart Volume): Letting the software extrapolate the natural ground level beneath the pile based on surrounding terrain data.26

- Comparison Surface: Calculating the volume difference between the current survey surface and a previous survey surface (to measure change) or a design surface (to measure cut/fill against plan).26

- Calculation: Once the boundaries and base are defined, the software employs algorithms (often based on comparing the top surface to the base surface within the defined perimeter) to compute the volume of the material with high precision.25 If the material’s density is known, the software can also calculate the tonnage.26

- Reporting: SimpliFly generates clear, comprehensive volumetric reports. These typically include the calculated volume (e.g., in cubic yards or cubic meters), tonnage (if density provided), material type, date of survey, a visual representation (map or image showing the measured pile), and potentially other metrics like surface area or perimeter length.26 Reports can often be customized and exported in standard formats like PDF.26

IV. Actionable Insights: Using SimpliFly Volumetric Data

SimpliFly delivers volumetric data that is not only accurate but also readily usable for improving site operations and decision-making.

- Deliverables Explained:

- Stockpile Reports: These reports provide the core quantitative data.26 Clear presentation includes volume, tonnage, material identification, date, and a map view for context. Understanding the calculation method used (e.g., smart volume vs. reference level) is important for interpretation.26

- 3D Models/Point Clouds: These allow for detailed visualization of stockpile shapes, identification of irregularities, and integration into larger site models.26 Visualizing the data, perhaps color-coded by elevation, can provide intuitive understanding of the pile’s form.46

- Orthomosaic Maps: These provide essential site context, showing the location of all stockpiles, equipment, and site features accurately.10 They serve as a base map for planning and communication.

- Change Detection Reports: By comparing volumetric surveys conducted at different times (e.g., start and end of a month), SimpliFly can precisely quantify the amount of material added or removed, crucial for tracking production, consumption, or earthwork progress.26

- Making Data Actionable: Accurate and timely volumetric data empowers site managers in numerous ways:

- Inventory Management: Regular drone surveys provide an accurate, up-to-date picture of on-hand material quantities, preventing costly stock shortages or wasteful over-ordering.25

- Financial Reporting & Forecasting: Reliable volume data supports accurate inventory valuation for financial statements and helps in forecasting future material needs.73

- Production Tracking: In mining or aggregate operations, frequent stockpile measurements allow managers to accurately track production rates and efficiency.25

- Earthwork Verification: Comparing drone-measured cut and fill volumes against design plans verifies progress and provides objective data for contractor payments.50

- Operational Planning: Knowing exact material quantities aids in planning logistics, resource allocation, and scheduling.

- Regulatory Compliance: Accurate volume data and site maps can be essential for meeting reporting requirements for landfills or mining operations.25

V. The Bottom Line: The Value of Drone-Based Volumetrics

Investing in drone technology for volume calculations delivers substantial returns through improved accuracy, efficiency, and safety.

- ROI Focus:

- Accuracy Pays: Preventing errors from inaccurate measurements avoids significant financial losses associated with over/underselling material, incorrect project bids, or disputes over quantities.26 The cost of the drone service is often quickly recouped through these accuracy gains.

- Efficiency Savings: Drastically reduced time and labor costs compared to traditional surveying methods provide direct operational savings.23 Avoiding site shutdowns further boosts productivity.

- Safety Benefits: While harder to quantify directly, preventing injuries by keeping personnel off stockpiles represents significant value in terms of avoided medical costs, lost time, and potential liability.25

- Demonstrated ROI: Case studies like Grade Tech show substantial savings ($90k on one job, $3.5k per day of avoided downtime) and significant revenue increases ($1.5M in a year) driven by the efficiencies enabled by drone surveying, which includes volumetrics.50

- Value Beyond Direct Cost:

- Improved Decision Making: Accurate, timely data leads to better operational planning and resource allocation.25

- Enhanced Inventory Control: Near real-time data provides unprecedented control over material stocks.73

- Better Collaboration & Dispute Resolution: Objective data serves as a single source of truth, minimizing conflicts.50

- Comprehensive Documentation: Digital records provide valuable historical data for analysis and reporting.40

The ability to conduct frequent, accurate measurements transforms inventory management from a periodic estimation exercise into a dynamic, data-driven process. This near real-time visibility allows for tighter control over operations, optimized production schedules, and more agile responses to changing demands or site conditions – a fundamental shift enabled by the efficiency of drone technology.23

VI. Partnering with SimpliFly: Your Volumetric Data Experts

SimpliFly provides accurate, reliable, and efficient drone-based volume calculation services tailored to the needs of the construction, mining, aggregates, and related industries.

- SimpliFly’s Approach: We understand the critical importance of accurate volumetric data. Our experienced team utilizes professional-grade drones equipped with high-resolution cameras (for photogrammetry) and/or precise LiDAR sensors, selected based on your project’s specific requirements for accuracy, speed, and site conditions. We employ rigorous flight planning and data capture protocols, often incorporating GCPs or RTK/PPK technology, to ensure the highest data quality.25 Our processing workflow uses industry-leading software to generate accurate 3D models and calculate volumes precisely. We deliver clear, concise reports in user-friendly formats, providing the actionable data you need. All operations are conducted safely by FAA-certified pilots in full compliance with regulations.12

- Why Choose SimpliFly: Achieving consistent, survey-grade accuracy with drones requires specialized equipment, sophisticated software, and trained personnel knowledgeable in both drone operations and surveying principles. Managing this in-house can be costly and complex.25 SimpliFly offers a turnkey solution, providing access to expert services and technology on demand, ensuring you get reliable volumetric data efficiently and cost-effectively.

- Call to Action: Stop guessing and start measuring with precision. Contact SimpliFly today for a consultation on how our drone volumetric services can improve your inventory management, streamline your operations, and enhance your bottom line.

VII. Conclusion: Precision Measurement Takes Flight

Drone technology has fundamentally changed the game for volume calculations in bulk material industries. By replacing slow, inaccurate, and often unsafe traditional methods with rapid, precise, and safe aerial surveys, drones provide managers with unprecedented accuracy and frequency in measuring stockpiles and earthworks. This data empowers smarter inventory management, optimizes production planning, reduces financial risk, and enhances operational efficiency. SimpliFly delivers these benefits through expert drone services, providing the accurate volumetric data needed to measure what matters most to your business success. As drone technology continues to integrate with AI and site management platforms, the ability to leverage real-time, accurate volumetric data will become an increasingly critical competitive advantage.