Powering Performance: How Drone Inspections Maximize Solar Farm Efficiency and ROI

I. Introduction: The Solar Energy Imperative

The global shift towards renewable energy has placed solar power at the forefront. For solar farm owners, operators, and asset managers, maximizing energy generation and ensuring long-term return on investment (ROI) are paramount.56 However, maintaining peak performance across vast arrays of solar panels presents significant challenges. Traditional inspection methods, often involving manual visual checks and handheld thermal cameras, can be incredibly time-consuming, labor-intensive, and costly, especially for utility-scale installations.56 Furthermore, these methods carry inherent safety risks for technicians working at height or navigating large ground-mount sites, and they may fail to detect subtle defects that can significantly impact energy output over time.56 Even minor defects, if left unaddressed, can lead to substantial energy losses and potentially shorten the lifespan of valuable assets.56

Enter drone technology. Unmanned Aerial Vehicles (UAVs) equipped with advanced sensors, particularly high-resolution thermal imaging cameras, are revolutionizing solar farm Operations and Maintenance (O&M).51 Drones provide a rapid, accurate, safe, and comprehensive method for inspecting entire solar farms, identifying a wide range of issues from individual faulty cells to widespread system anomalies. They have become an indispensable tool for ensuring optimal performance and protecting solar investments.51

This technological shift enables a crucial evolution in solar O&M strategy. Instead of relying on reactive maintenance (fixing problems only after they cause noticeable performance drops or failures), drone inspections facilitate a proactive and predictive approach.51 By detecting potential issues like hotspots, microcracking, or potential-induced degradation (PID) in their early stages, operators can intervene preventatively, minimizing energy loss, reducing costly downtime, preventing cascading failures, and ultimately maximizing the long-term value and reliability of the solar asset.51 Furthermore, the objective, detailed data generated by drones, especially when adhering to international standards like IEC 62446-3 60, provides crucial evidence for validating warranty claims, satisfying insurance requirements, and verifying performance guarantees. This documentation strengthens the financial security and operational integrity of solar projects, offering peace of mind to owners, investors, and insurers alike. SimpliFly specializes in leveraging this technology to deliver actionable insights for the solar industry.

II. The SimpliFly Advantage: Seeing Solar Differently

Partnering with SimpliFly for drone-based solar inspections provides a clear advantage over traditional methods, delivering superior data quality, efficiency, and safety.

- Rapid Inspections & Efficiency: Drones can inspect vast solar arrays with remarkable speed. A single drone can potentially inspect up to 20MW in a day, and multi-drone systems can cover even larger areas faster.53 This represents a dramatic improvement over manual methods, which can take weeks or months for large sites (e.g., reducing inspection time from two months to five days for a 900,000-panel site 59).51 Even logistics can be improved; drones have been used to transport hundreds of panels per day over difficult terrain, compared to only 15-20 manually.61

- Cost-Effective Maintenance: By identifying defects early and enabling targeted repairs, drone inspections significantly reduce overall O&M costs.51 Savings come from reduced labor hours for inspections, minimized system downtime due to faster diagnostics and repairs, prevention of costly major failures, and optimized maintenance schedules. Case studies demonstrate substantial potential financial losses avoided by addressing drone-detected issues.63

- Enhanced Safety: Drone inspections eliminate the significant safety risks associated with technicians climbing on rooftops or walking across large, potentially hazardous ground-mounted solar farms.51 Inspections are conducted remotely, keeping personnel safely on the ground.

- Improved Accuracy & Data Quality: Drones equipped with high-resolution thermal and visual cameras capture detailed data capable of detecting subtle anomalies often missed by the naked eye or handheld devices.51 Automated flight paths ensure consistent data capture across the entire array.53 Adherence to standards like IEC 62446-3 ensures the quality and reliability of the collected data, crucial for accurate diagnosis and documentation.60

- Comprehensive Data Collection: Drones can simultaneously capture multiple data types in a single flight, including visual imagery (RGB), thermal data, and potentially LiDAR data for site mapping or shading analysis.57 This provides a holistic view of the solar farm’s condition and environment, enabling detailed analysis and informed decision-making.57

SimpliFly utilizes drones equipped with sensors specifically chosen for solar applications:

- Thermal Cameras: These are the cornerstone of solar panel inspection. They detect variations in temperature across panel surfaces. Anomalies like “hotspots” (areas significantly warmer than surrounding cells) often indicate underlying issues such as malfunctioning cells, faulty connections, activated bypass diodes, or shading, all of which can reduce efficiency and potentially damage the panel.51

- High-Resolution RGB Cameras: These capture standard visual images, essential for identifying physical damage like cracks, shattering, delamination, frame damage, soiling (dirt, dust, bird droppings), vegetation encroachment, or issues with mounting structures and wiring.57 Visual data complements thermal data for accurate diagnosis.

- LiDAR (Primarily for Site Assessment/Design): While less common for routine O&M inspections, LiDAR sensors can be used during the pre-construction or expansion phases. They create highly accurate 3D topographic maps of the site, which are essential for optimizing panel layout, designing mounting structures, and performing precise shading analysis to maximize energy yield.57

The value of drone inspections extends across the entire solar project lifecycle. For EPCs, drone inspections during commissioning verify installation quality and provide a crucial baseline dataset.60 For O&M providers, regular drone inspections optimize maintenance schedules, reduce diagnostic time, and improve repair efficiency.23 For asset owners and managers, drone data validates performance, maximizes energy output, supports warranty claims, and provides critical insights for financial forecasting and asset valuation. This broad applicability underscores the versatility and strategic importance of drone technology in the solar industry.

III. Transforming Solar O&M: Key Drone Applications

SimpliFly’s drone services offer targeted solutions for critical aspects of solar farm operations and maintenance:

A. Thermal Inspections for Defect Detection

- How it Works: Drones equipped with sensitive thermal cameras fly systematic patterns over the solar array, capturing infrared images of every panel.51 Specialized software analyzes these images to identify thermal anomalies – areas that are significantly hotter or colder than expected relative to surrounding components.56 For maximum reliability and comparability, inspections can be conducted following international standards like IEC 62446-3, which specify requirements for image resolution, flight parameters, environmental conditions, and anomaly classification.60

- Defects Identified: Thermal inspections are highly effective at detecting a wide range of performance-impacting issues, including:

- Cell-level Hotspots: Indicating malfunctioning or damaged individual cells.56

- Bypass Diode Failures: Causing entire sections or strings of panels to underperform or go offline.56

- Offline Modules/Strings: Panels or entire strings not producing power due to connection issues or major faults.56

- Potential-Induced Degradation (PID): A gradual degradation often revealed by specific thermal patterns.60

- Microcracking: Tiny, often invisible cracks that can propagate and cause power loss, sometimes indicated by specific thermal signatures.58

- Soiling and Shading: Identifying panels whose performance is impacted by dirt, debris, or vegetation overgrowth.51

- Inverter/Combiner Box Issues: Detecting overheating components or entire malfunctioning units.60

- Faulty Connections/Wiring: Pinpointing areas with abnormal heat due to poor electrical connections.

- Benefits: Early detection of these defects is crucial. It allows O&M teams to perform targeted repairs before minor issues cause significant energy loss, lead to irreversible panel damage, or create safety hazards (like fire risks from overheating components).51 This proactive approach maximizes energy yield, extends the productive lifespan of the solar assets 56, improves overall system reliability 56, and provides the necessary documentation for successful warranty claims.60

- Deliverable: Detailed Inspection Reports featuring annotated thermal and corresponding visual images, precise location (GPS coordinates) of each anomaly, classification of defect type and severity, estimated power loss impact, and prioritization for repairs.

B. Visual Inspections & Site Monitoring

- How it Works: Drones capture high-resolution visual (RGB) photos and videos of the solar farm, covering panels, mounting structures, inverters, combiner boxes, fencing, and surrounding terrain.57 These flights can generate detailed orthomosaic maps providing a comprehensive overview of the entire site.57

- Benefits: Visual inspections identify physical damage not detectable by thermal cameras, such as cracked glass, frame damage, severe soiling, visible corrosion, loose wiring, or damage to mounting structures.58 They are also effective for monitoring site conditions like vegetation growth requiring management, soil erosion impacting foundations, potential security breaches, or tracking progress during the construction phase of new installations.65 Regular visual documentation creates a valuable historical record of site conditions.57

- Deliverable: High-Resolution Photos and Videos, Orthomosaic Site Maps, Site Condition Reports highlighting visual defects, vegetation issues, or structural concerns.

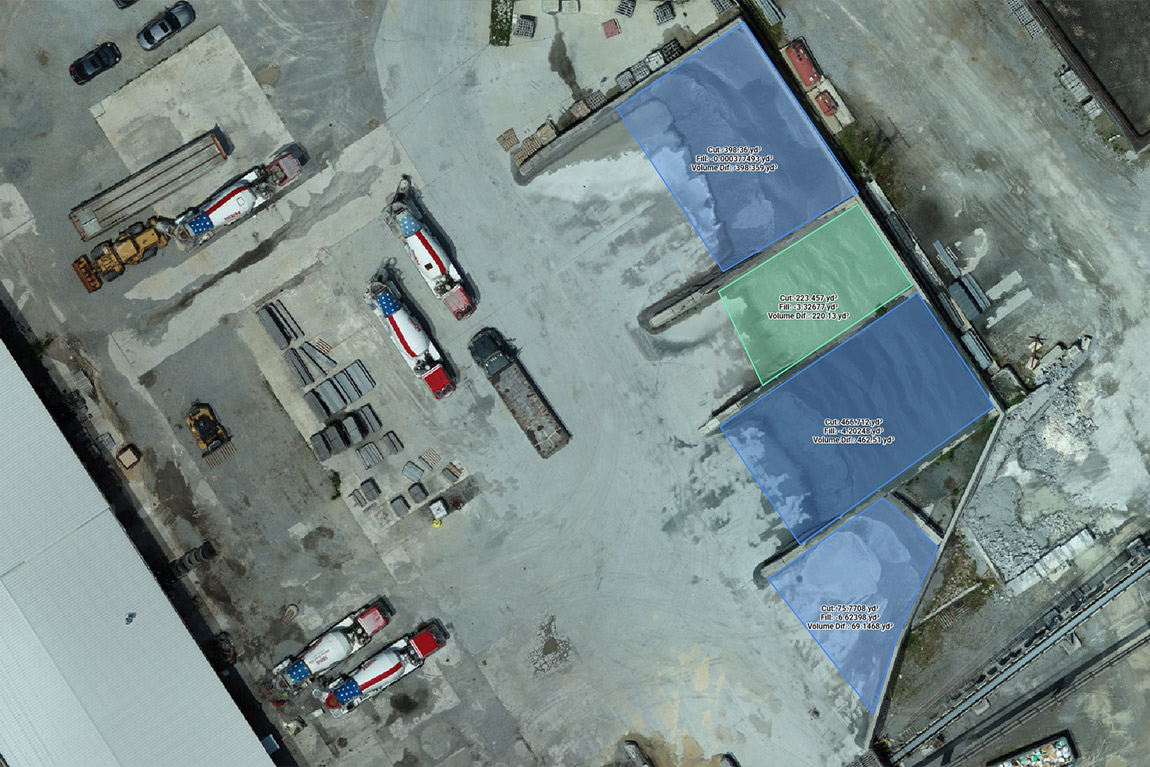

C. Site Assessment & Design Optimization (Pre-Construction/Expansion)

- How it Works: Before construction begins or when planning an expansion, drones equipped with RGB cameras and/or LiDAR sensors perform rapid and accurate site surveys.57 This data is used to create precise topographic maps showing elevation changes and terrain features.57 Drones can also capture data throughout the day to conduct detailed shade analysis, modeling how shadows from surrounding objects (trees, buildings) will impact the proposed array location across different times and seasons.58

- Benefits: Drone-based site assessments are significantly faster and often more accurate than traditional ground surveys.58 The precise topographic and shading data enables engineers and designers to optimize the solar array layout, panel placement, and mounting system design to maximize energy capture and minimize shading losses.57 This data-driven design process helps avoid costly errors, reduces project delays, and ensures the system is designed for optimal performance from day one. Potential installation challenges related to terrain or access can also be identified early.58

- Deliverable: High-Accuracy Topographic Maps (Contours, DEMs), 3D Site Models, Detailed Shade Analysis Reports, High-Resolution Orthomosaic Maps for site planning.

IV. Actionable Insights: Decoding Your SimpliFly Solar Data

SimpliFly transforms complex aerial data into clear, actionable intelligence for solar professionals. Understanding the deliverables is key to leveraging their full value.

- Deliverables Explained:

- Thermal Maps: These maps use color gradients to visualize temperature variations across the solar array.51 Warmer colors typically indicate potential issues like hotspots or malfunctioning components, while cooler areas might show inactive modules or strings. Presenting thermal images side-by-side with corresponding visual (RGB) photos provides crucial context for accurate diagnosis.66

- Defect Reports: These are the core actionable output. Reports meticulously document each identified anomaly, providing its precise GPS location, a clear visual and thermal image, classification by type (e.g., cell hotspot, diode failure, string offline, inverter fault) and severity (often linked to temperature difference or estimated power loss), and potential impact on performance.63 This allows O&M teams to quickly understand the scope and urgency of required maintenance. Reports adhering to standards like IEC 62446-3 provide standardized, reliable documentation.60

- Orthomosaics/Site Maps: These high-resolution maps provide a complete visual overview of the solar farm.57 They are invaluable for visualizing the spatial distribution of defects identified in the report, planning access routes for repair crews, and general site management tasks.

- Trend Analysis: By comparing inspection reports from multiple points in time (e.g., annual inspections), asset managers can track the evolution of defects, identify recurring problems, monitor degradation rates, and assess the effectiveness of maintenance interventions.56

- Making Data Actionable: SimpliFly reports are designed to drive action. O&M teams can use the prioritized defect list to schedule repairs efficiently, allocating resources to address the most critical issues first (those causing the largest power loss or posing safety risks).51 The precise location data guides technicians directly to the faulty components, minimizing search time. Standardized reports provide the objective evidence needed to initiate and validate warranty claims with manufacturers.60

The challenge of processing the vast amount of data collected from large utility-scale solar farms can be significant. Automating the analysis using Artificial Intelligence (AI) and machine learning algorithms can dramatically accelerate the identification, classification, and reporting of anomalies.51 AI can quickly sift through thousands of images, flag potential issues based on learned patterns, and pre-populate reports, allowing human experts to focus on verification and complex diagnostics. This makes scaling drone inspections across large portfolios more feasible and efficient.

Furthermore, integrating drone inspection data (the “physical health check”) with data from the solar farm’s existing SCADA system or asset management platform (the “electrical performance data”) creates a powerful, holistic monitoring system.40 Correlating thermal anomalies or visual defects identified by the drone with real-time or historical production data from specific inverters or strings allows for deeper diagnostics, helping pinpoint the root causes of underperformance with greater certainty.

V. The Bottom Line: Maximizing Solar ROI with Drones

Drone inspections offer a clear and substantial return on investment for solar farm owners and operators through multiple value streams.

- Quantifiable Impact: The financial benefits are directly measurable:

- Recovered Energy Loss: Case studies show drone inspections identifying issues causing significant power loss (e.g., 4.37%, 2.64%, 6.56% of site capacity) which translates to substantial annual financial losses if left unresolved (e.g., $184k, $17k per year in specific examples).63 Addressing these issues directly recovers lost revenue.

- Operational Efficiency: Inspection times can be reduced dramatically (e.g., by up to 400% 59), leading to significant savings in labor costs for O&M teams. Faster diagnostics also reduce mean time to repair (MTTR).

- Warranty Claim Success: Standardized drone data strengthens warranty claims, potentially saving significant costs on module or component replacements.60

- Key Value Drivers: Beyond immediate financial metrics, drones drive value by:

- Maximizing Energy Output: Ensuring panels operate at peak efficiency throughout their lifespan.56

- Reducing Downtime: Faster identification and resolution of issues minimize periods of underperformance or complete shutdown.56

- Extending Equipment Life: Proactive maintenance based on early defect detection prevents minor issues from escalating and causing premature failure.56

- Lowering O&M Costs: Reduced labor for inspections, targeted repairs, and prevention of major failures contribute to lower operational expenditures.51

- Improving Safety: Eliminating hazardous manual inspection tasks protects personnel.51

Crucially, the ROI of drone inspections often increases over the solar farm’s operational life. Early detection and correction of defects prevent cumulative energy losses and degradation that can compound significantly over 20-30 years. Regular drone inspections are therefore not just an operational expense, but a strategic investment in preserving the long-term value and maximizing the lifetime energy production of the solar asset.56

VI. Partnering with SimpliFly: Your Solar Inspection Specialists

SimpliFly provides specialized drone inspection services designed to meet the unique needs of the solar industry, ensuring assets perform optimally and deliver maximum returns.

- SimpliFly’s Approach: Our team possesses expertise in solar technology and O&M best practices.60 We utilize drones equipped with high-resolution thermal and visual sensors specifically suited for solar inspections.57 We adhere to industry best practices and can perform inspections compliant with standards like IEC 62446-3 upon request, ensuring data quality and reliability.60 Our process includes meticulous flight planning for efficient site coverage and safe execution by FAA-certified pilots.12 Most importantly, we deliver clear, concise, and actionable reports that pinpoint issues, quantify impact, and guide maintenance efforts effectively.56

- Why Choose SimpliFly: Developing an in-house drone program for solar inspections requires significant investment in specialized drones, thermal cameras, processing software, pilot training (including thermography expertise), and regulatory compliance management.51 SimpliFly offers a cost-effective, reliable alternative, providing access to expert pilots, cutting-edge technology, and efficient data analysis without the associated overhead and complexity.

- Call to Action: Ensure the health and performance of your solar assets. Contact SimpliFly today to schedule a consultation and learn how our expert drone inspection services can help you maximize energy generation, reduce O&M costs, and ensure the long-term success of your solar PV projects.60

VII. Conclusion: Illuminating the Future of Solar Performance

Drone technology has fundamentally changed the landscape of solar farm operations and maintenance. By providing a safe, rapid, and highly accurate means of inspecting vast solar arrays, drones are critical tools for identifying defects, optimizing performance, and maximizing the return on solar investments. SimpliFly stands ready to partner with solar owners, operators, and O&M providers, delivering the actionable aerial intelligence needed to ensure solar assets operate at peak efficiency. As the industry embraces trends like multi-drone operations for enhanced speed on large sites 53 and AI-driven analytics for predictive maintenance 51, drone inspections will become even more integral to the success and sustainability of solar energy.

Proposed Table for Solar Blog: Common Solar Defects Detectable by Drones

| Defect Type | Visual Indicator (Thermal/RGB) | Potential Impact |

| Hotspots (Cell/Module Level) | High Temp Area (Thermal) | Reduced Efficiency, Panel Damage |

| Bypass Diode Failure | Section/String Underperforming/Hot (Thermal) | Significant Section/String Power Loss |

| Offline Module/String | Cold Module/String (Thermal), No Output (SCADA) | Complete Power Loss from Module/String |

| Microcracking | Specific Hotspot Patterns (Thermal), Visible (RGB) | Power Loss, Accelerated Degradation |

| Soiling/Vegetation Shading | Obscured Panel (RGB), Cooler Areas (Thermal) | Reduced Output due to Shading/Blockage |

| Inverter/Combiner Box Faults | Overheating Unit (Thermal), Multiple Strings Down | Major Power Loss from Affected Area, Safety Risk |

| PID (Potential-Induced Degrad.) | Subtle String/Module Temp Patterns (Thermal) | Gradual Degradation of Output Over Time |

| Physical Damage (Cracks, etc.) | Visible Defects (RGB) | Reduced Output, Safety Hazard, Moisture Ingress |

Value Reasoning: This table provides a clear, concise reference for solar asset managers linking specific, common defects to how SimpliFly’s drones detect them (thermal/visual cues) and why it matters (potential impact). It translates technical jargon into understandable issues and consequences, reinforcing the diagnostic power and value of drone inspections for maintaining asset health and performance.